Products

Navigation

Send Us A Message

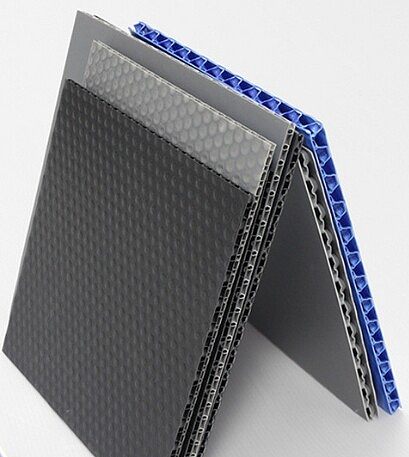

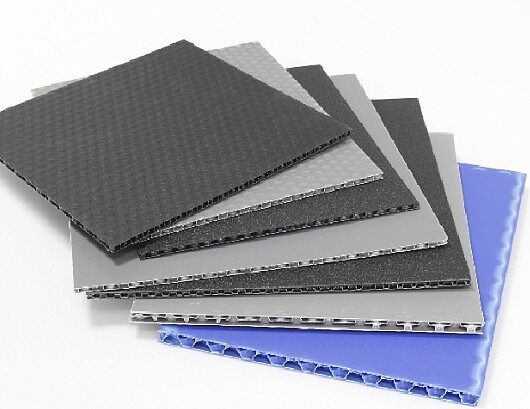

Unlike the PP sandwitch honeycomb panel extrusion machine that emphasizes multi-layer bonding, this machine focuses on one-step core-surface integration, reducing production time. A vacuum calibration unit and air-cooling system work together to stabilize the honeycomb structure, preventing cell deformation during shaping. The servo-driven haul-off maintains consistent tension, while a precision cutting system trims panels to custom lengths with ±2mm accuracy.

Equipped with a PLC touchscreen, operators can adjust extrusion speed, layer thickness, and cooling parameters in real time. Compared to the Polypropylene honeycomb board extrusion machine, it offers better composite layer adhesion and cell uniformity. With output rates of 120–450 kg/h, it supports recycled PP (up to 40%) and caters to diverse needs: lightweight packaging pallets, furniture panels, and automotive door trims. Its modular design simplifies maintenance, and wear-resistant components ensure long service life, making it a reliable choice for efficient PP honeycomb composite panel production.

1. What is the energy consumption during equipment operation?

Our equipment uses energy-saving motors and heating systems, resulting in energy consumption 8%-12% lower than conventional equipment in the industry (for example, a PVC foam board line consumes approximately 50-80 kWh per hour, depending on production capacity). If your existing equipment consumes high energy, you can contact us for upgrade solutions (such as replacing energy-saving motors and optimizing temperature control systems) to help reduce long-term operating costs.

2. Can the equipment be adapted to different raw materials?

For example, what adjustments are required when switching from PVC to PP?

Some equipment supports multiple raw materials (this must be specified in the customization proposal). When switching from PVC to PP, screw speed, heating temperature, and mold parameters must be adjusted. Our engineers will provide detailed adjustment guides. If core components need to be replaced (such as screws adapted for different raw materials), we can provide genuine spare parts and replacement services to ensure normal operation of the equipment after the switch.

3. How long does it take from ordering to delivery of the equipment?

The delivery time for standard equipment (such as small plastic pipe production lines) is approximately 30-45 days. Customized production lines (such as large PVC building formwork production lines) are approximately 45-60 days, depending on the complexity of the solution. Regarding overseas logistics, sea freight to near-sea markets (such as Southeast Asia) takes approximately 7-15 days, while sea freight to ocean markets (such as the Americas and Africa) takes approximately 25-40 days. We will track the logistics progress throughout the entire process to ensure timely delivery.

Please Contact Us

Recommendation

Send Your Inquiry

We welcome your cooperation and we will develop with you.