Products

Navigation

Send Us A Message

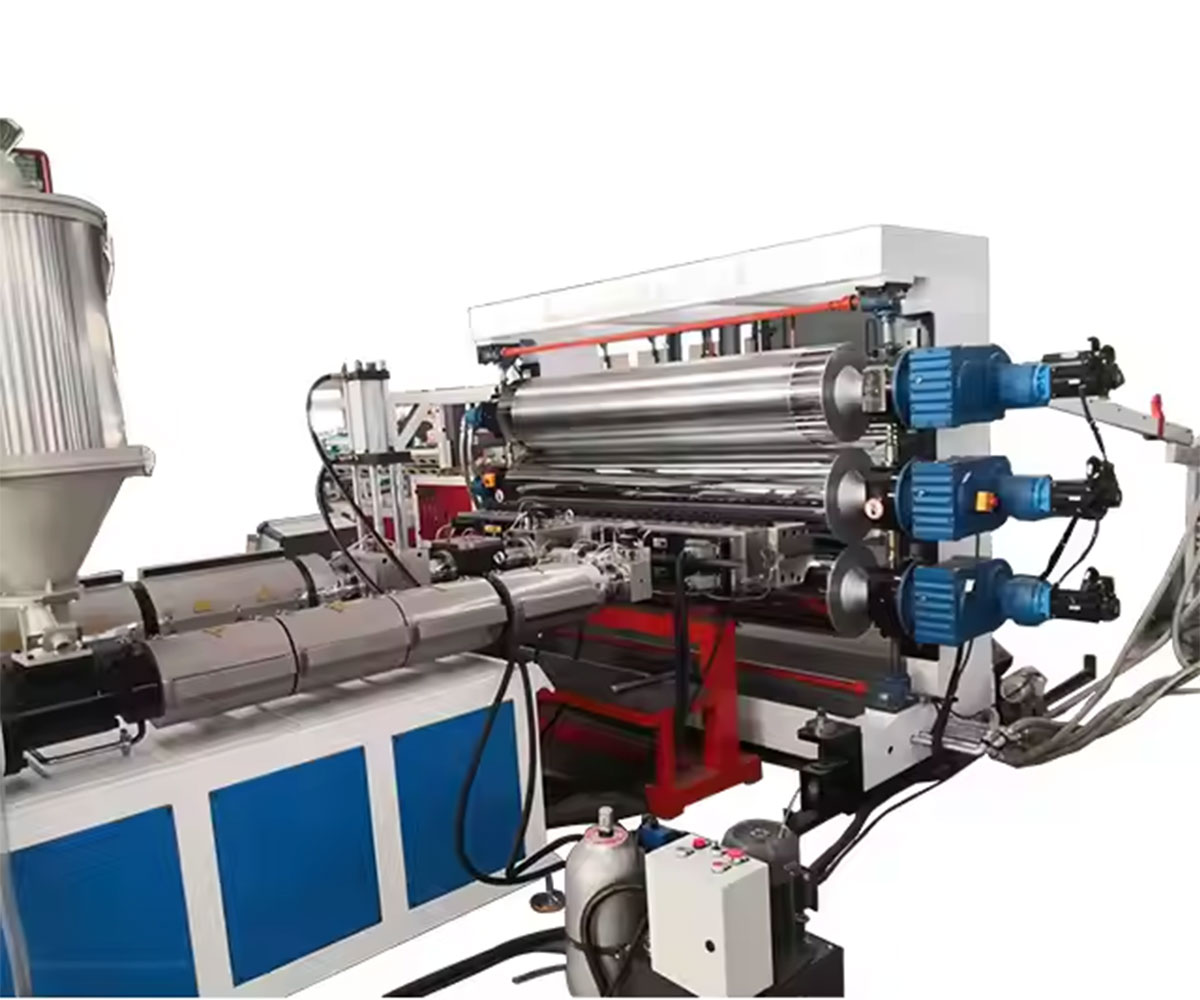

Equipped with a 100mm single-screw extruder (L/D 35), the PE waterproof membrane making machine enables stable PE melting (180-210℃ adjustable) with a high-output screw design—ensuring uniform material flow for wide-width films, a critical requirement for reliable Large-scale wide-width waterproof roll extrusion machine. The shaping mold uses a T-die with precision lip adjustment (±0.05mm), ensuring even thickness across the entire width, while a multi-roller cooling unit rapidly solidifies the membrane to avoid wrinkling.

For large-scale production, the Large-scale wide-width waterproof roll extrusion machine adopts a servo-driven haul-off system (speed 1-10m/min adjustable) with synchronous traction—preventing membrane stretching or deviation during rolling. It also has an automatic edge trimming unit that cuts irregular edges, ensuring roll neatness, and a winding unit with tension control to avoid roll loosening.

Operation uses an 8-inch touchscreen HMI, displaying real-time data (melting temp, haul-off speed, roll length) and storing 30+ recipes. The PE waterproof membrane making machine is equipped with a thickness gauge that alerts if deviations occur, protecting product quality. It also integrates a PE material drying system to remove moisture (≤0.1%), avoiding bubbles in the membrane.

Safety features include over-temperature alarms, motor overload protection, and emergency stops, meeting CE and ISO 9001. Built with wear-resistant components (nitrided steel screws, chrome-plated cooling rollers, Siemens PLC), it has an average failure rate below 2% per year and 8-10 years service life. Optional accessories: membrane embossing unit (for anti-slip texture), leak-testing system, and roll packaging machine. A 12-month warranty covers parts/labor with on-site support—ideal for manufacturers producing large-width PE waterproof rolls for construction.

1. What is the energy consumption during equipment operation?

Our equipment uses energy-saving motors and heating systems, resulting in energy consumption 8%-12% lower than conventional equipment in the industry (for example, a PVC foam board line consumes approximately 50-80 kWh per hour, depending on production capacity). If your existing equipment consumes high energy, you can contact us for upgrade solutions (such as replacing energy-saving motors and optimizing temperature control systems) to help reduce long-term operating costs.

2. Can the equipment be adapted to different raw materials?

For example, what adjustments are required when switching from PVC to PP?

Some equipment supports multiple raw materials (this must be specified in the customization proposal). When switching from PVC to PP, screw speed, heating temperature, and mold parameters must be adjusted. Our engineers will provide detailed adjustment guides. If core components need to be replaced (such as screws adapted for different raw materials), we can provide genuine spare parts and replacement services to ensure normal operation of the equipment after the switch.

3. How long does it take from ordering to delivery of the equipment?

The delivery time for standard equipment (such as small plastic pipe production lines) is approximately 30-45 days. Customized production lines (such as large PVC building formwork production lines) are approximately 45-60 days, depending on the complexity of the solution. Regarding overseas logistics, sea freight to near-sea markets (such as Southeast Asia) takes approximately 7-15 days, while sea freight to ocean markets (such as the Americas and Africa) takes approximately 25-40 days. We will track the logistics progress throughout the entire process to ensure timely delivery.

Please Contact Us

Recommendation

Send Your Inquiry

We welcome your cooperation and we will develop with you.