Products

Navigation

Send Us A Message

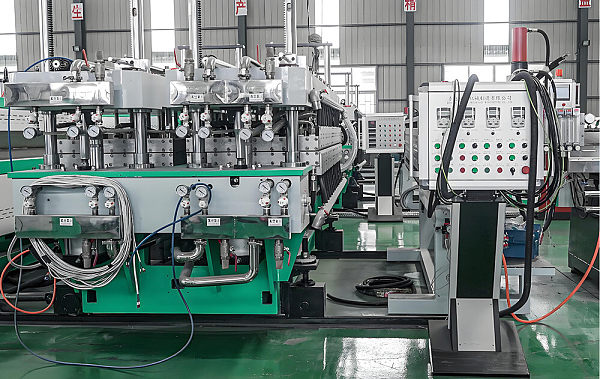

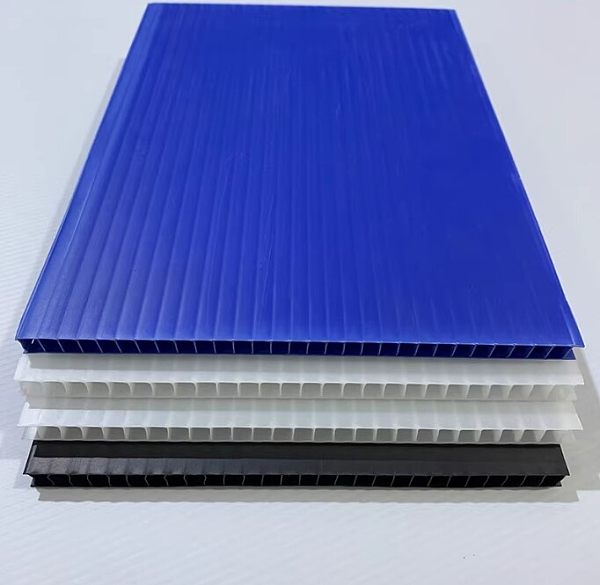

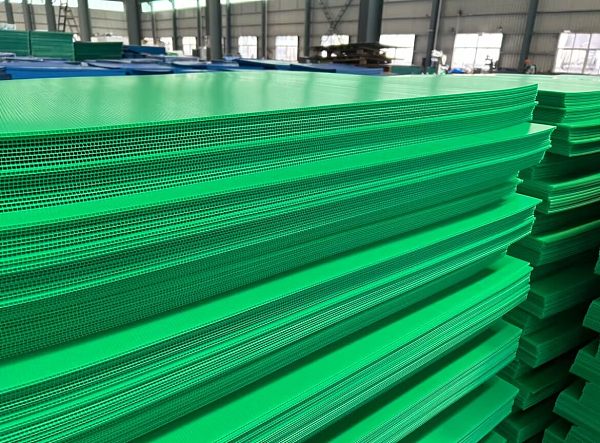

Unlike the PC corrugated board extrusion machine which focuses on wave-shaped profiles, this machine specializes in lattice-patterned plates, leveraging a water-cooled calibration sleeve and immersion cooling tank to lock in dimensional stability—critical for large-width plates prone to warping. The servo-driven haul-off unit maintains steady traction, paired with a flying cutter for ±1mm length accuracy, minimizing waste.

Equipped with a PLC touchscreen, it allows real-time adjustment of screw speed, cooling temperature, and haul-off rate. It achieves output rates 80–400 kg/h, compatible with UV-stabilized or flame-retardant PC blends. Ideal for advertising display boards (high transmittance) and greenhouse panels (impact resistance), it also supports multi-layer co-extrusion for enhanced functionality. Its durable components (nitrided barrel, wear-resistant screw) ensure 8–10 years of service, making it a cost-effective choice for manufacturers seeking high-performance PC hollow grid plate production.

1. What is the energy consumption during equipment operation?

Our equipment uses energy-saving motors and heating systems, resulting in energy consumption 8%-12% lower than conventional equipment in the industry (for example, a PVC foam board line consumes approximately 50-80 kWh per hour, depending on production capacity). If your existing equipment consumes high energy, you can contact us for upgrade solutions (such as replacing energy-saving motors and optimizing temperature control systems) to help reduce long-term operating costs.

2. Can the equipment be adapted to different raw materials?

For example, what adjustments are required when switching from PVC to PP?

Some equipment supports multiple raw materials (this must be specified in the customization proposal). When switching from PVC to PP, screw speed, heating temperature, and mold parameters must be adjusted. Our engineers will provide detailed adjustment guides. If core components need to be replaced (such as screws adapted for different raw materials), we can provide genuine spare parts and replacement services to ensure normal operation of the equipment after the switch.

3. How long does it take from ordering to delivery of the equipment?

The delivery time for standard equipment (such as small plastic pipe production lines) is approximately 30-45 days. Customized production lines (such as large PVC building formwork production lines) are approximately 45-60 days, depending on the complexity of the solution. Regarding overseas logistics, sea freight to near-sea markets (such as Southeast Asia) takes approximately 7-15 days, while sea freight to ocean markets (such as the Americas and Africa) takes approximately 25-40 days. We will track the logistics progress throughout the entire process to ensure timely delivery.

Please Contact Us

Recommendation

Send Your Inquiry

We welcome your cooperation and we will develop with you.